|

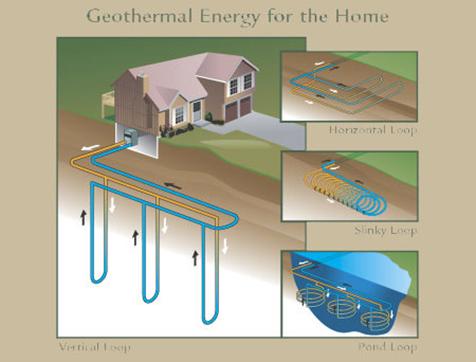

Geothermal ground loop systems use the earth as a heat source and heat sink. A series of pipes, commonly called a loop, carry a fluid used to connect the geothermal system's heat pump to the earth. There are different types of ground loops, a open loop or a closed loop. A open loop will pull water from its resources then utilize it transferring the energy then discharging it back out to its designed or designated place. This is normally from ponds or vertical ground well systems. A closed loop is utilizing the same fluid in a closed loop circuit made of pipe or tubing. Once used it is released back into the loop system where the energy is transferred and then recycled to be used again. |

|

Geothermal Ground Loop |

|

Geothermal heating and cooling does not rely on the outside temperature. The outdoor air temperatures fluctuate and change with the seasons, but the underground temperatures remain virtually the same. Depending on your geographic location , four to six feet below the earth’s surface the temperatures remain around 56 degrees. Geothermal systems, which typically consist of an indoor unit and a buried earth loop, using the earth’s constant temperature to provide “free” energy. |

|

Open loop systems are one of the simplest in design. There are several types of open loop designs. The well design, used for decades, the ground water is drawn from an aquifer through one well, passes through the heat pump's heat exchanger, and is discharged to the same aquifer through a second well, in most all designs, at a distance from the first. These can be man made aquifers or water pulled for a pond, lake, or river. Open loops are a popular, but some designs using a open loop, in some areas, discharging into a certain locations are not permitted. With increasing environmental concerns, compliances, regulations, and water usages now monitor water discharge methods. This loop system is widely used where a river, lake or pond exist. The 4” to 5” well system is used when location has a small land area. A lot of installation have been used in shallow system, discharging the water onto landscaping. This has raised concerns with the consumption of water usages. For clean lakes and ponds a simple pump and dump systems can be used. Returning the water back into the lake or pond. Do you have a lake or pond access? |

|

The ground loop is a key part of the geothermal system and it must be properly designed and installed. The plans to the loop ground field are easy to understand but applying the technology to the design is quite complicated. Careful design is necessary to ensure that there is sufficient capacity available for the geothermal heat pump to operate properly. Design consideration is crucial when spacing the pipes in a loop and is important as this affects how much the heating or cooling effect of one pipe influences the heat source or heat sink available to adjacent pipes. |

|

Open Loop |

|

Closed loop designed systems are becoming the most common type of geothermal source. Closed loops utilize polyethylene piping buried or drilled into the ground, filled with a fluid mixture of water/anti-freeze solution. The loop fluid circulating in this closed piping (Closed Circuit) system absorbs heat or rejects heat into the surrounding earth.

Taking an inventory of all available resources both man made and natural will help in deciding what type of Geothermal Design loop system is most efficient for the geographic location of installation. There are two types of ground closed loop designs vertical or horizontal loops. |

|

Vertical loops are most common in commercial applications and require the least ground area for installation with little disturbance to the ground surface. For residential systems, holes are most commonly drilled to a depth of 150-200 ft and are spaced a minimum of 10 ft apart. In most regions, as a rule, one hole is required for each ton (12,000BThU/h) of heating or cooling depending somewhat on the subsurface material.

Most installers usually use a water well rig to drill the holes therefore access to the drilling area for a truck is necessary. When the pipe has been inserted the hole a heat conductive grout is being applied. This serves several purposes, ensures good heat communication between the pipe and the ground, and also seals the hole so that there can be no groundwater contamination or flow within the hole. From each vertical loop a trench is dug between the holes and one leading to the house to a depth of about 3 ft. The pipes are connected together by using a manifold pipe. |

|

Vertical Loop |

|

Closed loops are virtually maintenance free, and since they re-circulate the same fluid there is no water to discharge. However, closed loops, due to the excavation costs, are generally more expensive than open loop systems |

|

Horizontal Loop |

|

Horizontal loops use polyethylene pipe buried trenches at a depth of 6-8 feet or in a larger pit at a depth of about 10 ft. Trenches can be anywhere up to 150ft long depending on the pipe configuration. The geothermal pipe can be laid in a trench in long straight lengths on each side of the trench, and sometimes at 2 levels in each trench. This requires trenches at least 3 ft wide. Another approach is becoming popular, a slinky configuration is used and the pipe is laid in a trench about 5 ft wide in a semi-coiled manner. Each trench often provides 1 ton of heating or cooling although this depends very much on the pipe configuration and the type of ground. The horizontal design requires a sizable area of land depending on the required of heating or cooling needed. For new construction, there can be some cost savings compared to a vertical loop particularly if digging machines are already available at the site. |

|

Slinky Loops |

|

Slinky coil loops are latest in ground loop design. The overlapping coils made of polyethylene pipe are used to increase the heat exchange per foot of trench length, but require more pipe per ton of capacity. A two-pipe systems may require 200 to 300 feet of trench per ton of nominal heat exchange capacity. The trench length decreases as the number of pipes in the trench increases or as Slinky coil overlapping increases. This same slinky coil system can be used in a lake or pond application. |

|

Need help? Call:

(512) 704-8200

(229) 638-2889

Submit Question Email Us:

info@geothermalsolutions.net |